by admin | Jun 10, 2025 | Engineering

Client Profile / Industry Context

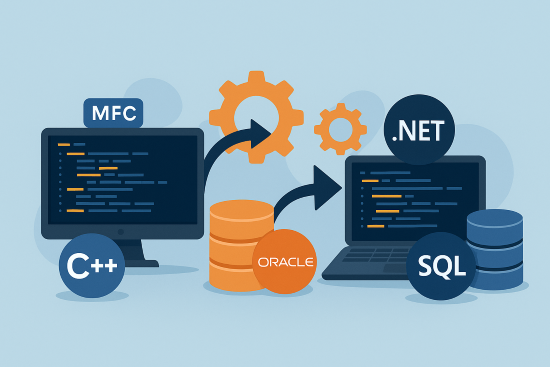

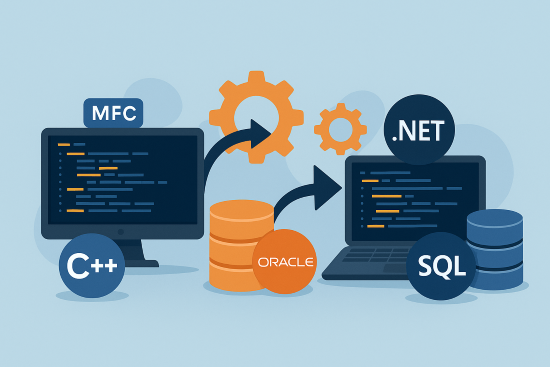

Our client, a leading enterprise software solutions provider operating in highly regulated industries, faced mounting challenges managing aging mission-critical applications. Over the years, their legacy VC++ desktop systems and Oracle databases became difficult to maintain, scale, and integrate into modern cloud-first enterprise ecosystems. To maintain competitive advantage and ensure long-term sustainability, a full-stack modernization program was initiated.

The Challenge / Trigger

The client’s core business applications were originally developed over a decade ago using VC++, MFC, proprietary libraries, and Oracle PL/SQL. These systems supported complex workflows but had become fragile due to:

-

Lack of functional documentation and highly entangled code structures.

-

Tight coupling of business logic within the UI layer.

-

Obsolete custom-built VC++ libraries no longer supported.

-

Difficulty integrating legacy apps with modern web platforms.

-

Rising Oracle licensing and maintenance costs.

-

Limited scalability and future readiness.

With growing business demands, cloud adoption, and user expectations for responsive web-based experiences, a comprehensive modernization was no longer optional — it was a business-critical imperative.

What We Delivered

| Service Type |

What We Did |

| Legacy Code Understanding & Reverse Engineering |

Deployed expert legacy application team to analyze VC++ code structure, global variables, and custom data structures. Paired developers with business users to extract undocumented functional behavior. |

| VC++ to .NET Migration |

Refactored procedural VC++ code into modular C# ASP.NET MVC architecture using repository patterns, dependency injection, and layered separation of concerns. |

| Custom VC++ Library Replacement |

Replaced obsolete VC++ libraries with modern .NET equivalents like System.IO, System.Math, and serialization frameworks; developed C++/CLI wrappers for critical legacy functions. |

| Desktop-to-Web UX Modernization |

Redesigned complex MFC user interfaces into responsive, mobile-ready web applications using Razor Pages, Bootstrap, AJAX, and SignalR for real-time updates. |

| State Management Transition |

Implemented distributed session management, TempData, and caching strategies for stateless web architecture. |

| Authentication & Authorization Upgrade |

Replaced legacy hardcoded authentication with ASP.NET Identity and role-based access management using Active Directory integration. |

| Data Access Transformation |

Migrated from embedded DBI calls to ORM-driven data access using Entity Framework Core with Code First and Database First strategies. |

| Error Logging & Observability |

Integrated structured logging using Serilog, Application Insights, and proactive crash analytics. |

| Oracle to SQL Server Database Migration |

Full-scale conversion of PL/SQL stored procedures, triggers, cursors, and sequences to T-SQL equivalents, utilizing SSMA and custom scripts. |

| Data Transfer Optimization |

Migrated billions of rows using parallel BCP, SSIS batch mode, and delta copy synchronization for minimal downtime cutover. |

| Data Validation & Testing |

Employed hash-based record-level diffing tools to ensure complete data integrity across platforms. |

| Environment & Test Matrix Setup |

Established multi-browser, multi-device QA environments simulating real-world customer usage. |

Before vs After (Transformation Snapshot)

| Metric |

Before Migration |

After Modernization |

| Code Maintainability |

Fragile monolithic VC++ |

Modular, service-oriented .NET |

| UI Responsiveness |

Desktop-only MFC |

Responsive Web UX |

| Business Logic |

UI-coupled procedural code |

Decoupled MVC architecture |

| Authentication |

Hardcoded Windows Auth |

ASP.NET Identity, AD Integration |

| Reporting Speed |

Manual multi-step extracts |

Real-time dashboards |

| Database Cost |

High Oracle licensing |

Optimized SQL Server costs |

| Data Validation |

Manual, error-prone |

Automated checksum validation |

| Change Deployment |

High risk, downtime |

CI/CD enabled with rollback support |

| Observability |

No central logs |

Full observability via Application Insights |

Outcome & Business Impact

-

Reduced operational overhead by 40% through technology stack consolidation.

-

Eliminated significant Oracle licensing costs with full SQL Server migration.

-

Improved system performance and scalability for future growth.

-

Enabled cloud-readiness and integration flexibility with modern APIs.

-

Minimized end-user disruption via carefully staged cutover plans.

-

Strengthened security posture with role-based access control and structured authentication mechanisms.

How the Client Viewed Us

Rigel Networks delivered far beyond traditional development—they were our modernization partner. Their ability to reverse-engineer legacy systems, deeply understand both technology and business logic, and execute flawlessly made this complex transition seamless.”

-

Trusted Partner for Legacy Modernization

-

Technology Advisor for Future-State Architecture

-

Full Delivery Ownership with Minimal Client Overhead

Key Takeaways

✔ Legacy modernization is not a simple code migration — it’s a holistic business enablement exercise.

✔ Reverse engineering expertise reduces long-term technical debt.

✔ Pairing domain-aware teams with business SMEs unlocks hidden functional knowledge.

✔ Database replatforming requires hybrid automation + expert manual tuning.

✔ Full-stack modernization drives both cost savings and strategic flexibility.

Related Solutions / Engagements

Welding Process Specification Manager (for same client’s QA system)

Digital Signature Workflow (deployed in subsequent phases)

Enterprise Document Management Platform (modernization of older file-based workflows)

Let’s Discuss Similar Outcomes for You

Looking to modernize your legacy VC++, Oracle, or MFC-based systems? Whether you’re struggling with skill gaps, documentation black holes, or complex migrations, we bring proven frameworks and deep technical expertise.

presales@rigelnetworks.com | www.rigelnetworks.com

by admin | Jun 6, 2025 | Engineering

In heavy engineering and fabrication industries, welding sits at the heart of structural integrity and product performance. However, ensuring consistent welding quality across complex shop-floor environments often remains a major challenge — driven by human variability, fragmented inspection processes, and limited traceability.

Poor welds can lead to costly rework, non-compliance with industry standards, and, most critically, product failures in the field. Traditional paper-based inspection logs and disconnected quality checks often fail to capture real-time defects or systemic root causes.

Our Quality Control Protocols with Shop Welding Enhancement solution transforms this scenario by fully integrating welding processes with AI-powered defect detection, structured inspection protocols, digital documentation, and actionable analytics — ensuring every weld meets design intent, regulatory compliance, and safety standards with complete traceability.

Key Use Cases & Capabilities

1. Centralized Storage of WPQR/WPS Documentation

Digitally store and manage Welding Procedure Qualification Records (WPQR) and Welding Procedure Specifications (WPS) in a secure repository.

Benefits:

-

-

Instant access for audits, compliance checks & production teams

-

Eliminates paperwork and version control issues

-

Quick retrieval for inspections and approvals

2. Automated Qualification Expiry Alerts

Set automated expiry notifications for welder certifications, WPS validations, and qualification renewals.

Benefits:

-

-

Prevents unqualified personnel from performing critical welds

-

Ensures continuous regulatory compliance

-

Simplifies workforce certification management

3. Pre/Post-Weld Inspection Checklists

Digital inspection templates ensure consistent data capture for pre-weld preparation and post-weld evaluations.

Benefits:

-

-

Eliminates checklist variations across inspectors

-

Ensures 100% coverage of inspection points

-

Early detection of potential weld quality risks

4. In-Process Weld Inspections

Enable real-time inspections during welding operations, capturing parameters such as heat input, travel speed, and filler material usage.

Benefits:

-

-

Identify deviations early before weld completion

-

Reduce scrap and rework costs

-

Continuous process control aligned with design specifications

5. Root Cause Analysis & Defect Trend Monitoring

Use AI-powered defect detection and historical analysis to identify recurring quality issues, material variances, and operator errors.

Benefits:

-

-

Data-driven improvement of welding processes

-

Early identification of systemic issues

-

Supports continuous improvement and Six Sigma initiatives

6. Weld Repair & Rework Management

Digitally log, track, and analyze weld repairs with full traceability from defect identification to corrective action closure.

Benefits:

-

-

Reduce repeated repair cycles

-

Detailed analytics for cost-of-quality reporting

-

Clear accountability and audit trails

Role-Based Access & Interfaces

Role

|

Key Actions & Interface

|

| Welding Supervisor |

Schedule inspections, assign qualified welders, review inspection results |

| Quality Inspector |

Conduct digital inspections, record findings, flag defects |

| Production Manager |

Monitor quality KPIs, track repair activities, authorize work releases |

| Compliance Officer |

Access audit-ready documentation, verify certifications, generate compliance reports |

| Admin |

Manage user roles, configure checklists, update WPS database |

Before vs After – Problem Solving Matrix

Old Problem

|

New Digital Solution

|

| Paper-based weld records |

Centralized digital WPQR/WPS repository |

| Missed welder qualification expiries |

Automated certification alerts |

| Inconsistent inspection processes |

Standardized digital checklists |

| Reactive defect management |

AI-powered real-time defect detection |

| Poor traceability for repairs |

Full rework tracking with audit trails |

Analytics & Dashboards

-

-

Weld Defect Heatmap

-

Certification Expiry Dashboard

-

Rework & Repair Cost Analysis

-

Inspection Compliance Rate

-

Operator-wise Defect Frequency

-

Root Cause Categorization Reports

Use Case Impact – Real Industry Examples

Example 1: Offshore Platform Fabricator

Example 2: Heavy Equipment Manufacturer

Example 3: EPC Contractor for Power Plants

Why Choose This Solution?

-

-

Fully digitizes welding quality management lifecycle

-

Seamless ERP, MES, and PLM integration

-

Enables AI-powered predictive quality improvement

-

Supports global compliance standards (ASME, AWS, ISO)

-

Scalable for multi-factory and multi-project environments

-

Increases throughput while reducing cost of quality

Get Started

Looking to build world-class welding quality programs with full digital integration? Let us show you how our Shop Welding Enhancement Solution can reduce defects, control costs, and safeguard compliance.

[Click here to schedule a demo]

by admin | Jun 6, 2025 | Engineering

Industrial assets—whether in heavy engineering, oil & gas, power plants, or aerospace—demand unrelenting reliability. Failure to detect hidden flaws early can escalate into catastrophic breakdowns, safety hazards, and costly downtimes. Traditional Non-Destructive Evaluation (NDE) methods, while effective, often suffer from fragmented data capture, paper-based reporting, and subjective interpretations.

Our Non-Destructive Evaluation Examination Software transforms this critical inspection process into a fully digitized, predictive, and compliance-aligned workflow. By unifying inspection data, predictive defect analysis, and global standard validations under one platform, we enable proactive maintenance strategies, traceable inspections, and accelerated decision-making—minimizing risk while maximizing operational continuity.

Key Use Cases & Capabilities

1. Multi-Technique NDE Method Support

Supports Ultrasonic Testing (UT), Radiographic Testing (RT), Magnetic Particle Testing (MT), and Penetrant Testing (PT) seamlessly in one unified system.

Benefits:

-

- Centralized inspection data across multiple techniques

- Simplified training & certification compliance

- Faster cross-method correlation for defect validation

2. Predictive Defect Detection & Early Warning

AI-powered algorithms analyze inspection data to identify defect patterns, severity scoring, and potential failure progression.

Benefits:

-

- Early detection of high-risk anomalies

- Reduction in unscheduled downtime

- Proactive maintenance scheduling

3. Compliance & Standards Validation Modules

Pre-built validation engines ensure inspections comply with ASME codes, ISO 9712 standards, and industry-specific regulations.

Benefits:

-

- Real-time compliance alerts

- Reduced audit preparation time

- Lower liability exposure during inspections

4. Digitized Inspection Reports & Traceability

Complete elimination of paper-based reporting with real-time data capture via mobile devices and handheld scanners.

Benefits:

-

- Immediate report generation

- Full traceability for every inspection cycle

- Simplified data retrieval for audits & certifications

5. Centralized Defect Library & Knowledge Base

Continuously updated defect reference models, historical case studies, and standard defect categorizations.

Benefits:

-

- Standardized defect classification

- Consistent decision-making across inspectors

- Continuous improvement from historical trends

6. Visual Data Analytics with Heat Maps & 3D Visualization

Overlay inspection data on 3D models or asset diagrams for quick identification of risk zones.

Benefits:

-

- Visual clarity for maintenance teams

- Quick isolation of failure-prone zones

- Data-backed resource allocation for repairs

7. Integration with ERP & Asset Management Platforms

Seamless API-based integration with enterprise-level systems for synchronized operations.

Benefits:

-

- Unified asset health records

- Reduced data silos across operations

- Automated maintenance triggers based on inspection outcomes

Role-Based Access & Interfaces

Role

|

Key Actions & Interface

|

| Inspection Engineer |

Conduct inspections, log defect data, upload images |

| Quality Manager |

Review defect severity, approve inspection cycles, compliance validation |

| Maintenance Planner |

Schedule repairs based on defect risk scores |

| Compliance Officer |

Verify reports, track regulatory adherence |

| Admin |

Manage users, assign inspection permissions, configure compliance standards |

Before vs After – Problem Solving Matrix

Old Problem

|

New Digital Solution

|

| Fragmented paper-based inspection logs |

Fully digitized inspection data capture |

| Subjective defect interpretation |

AI-powered defect scoring and analysis |

| Reactive maintenance after failure |

Predictive maintenance based on early defect detection |

| Manual compliance validations |

Automated ASME, ISO 9712 compliance checks |

| Disconnected systems across inspection & maintenance |

Unified platform with ERP integration |

Analytics & Dashboards

-

- Asset Health Index across equipment

- Defect type frequency trends

- Inspector-wise performance analytics

- Real-time compliance gap alerts

- Inspection backlog & overdue reports

- Cost of deferred maintenance analysis

Use Case Impact – Real Industry Examples

Aerospace Component Manufacturer:

Reduced recurring structural failures by 35% using predictive defect alerts from early ultrasonic inspection data.

Oil & Gas Pipeline Operator:

Achieved 50% faster compliance audits with digitized reports aligned to ASME standards.

Heavy Machinery Fabricator:

Lowered unscheduled downtime incidents by 40% after shifting to predictive maintenance triggers via NDE analytics.

Why Choose This Solution?

-

- Comprehensive NDE technique coverage (UT, RT, MT, PT)

- Embedded ASME & ISO 9712 compliance engines

- AI-powered predictive defect analytics

- Visual 3D mapping for faster defect localization

- Role-based interfaces for inspectors, quality, and planners

- Seamless ERP, CMMS & asset management integrations

- Proven industry impact with measurable ROI

Get Started

Is your current NDE process reactive, manual, or fragmented? Discover how our Non-Destructive Evaluation Examination Software can help you shift from reactive firefighting to proactive asset health management.

Click here to schedule a demo

by admin | Jun 6, 2025 | Engineering

In the world of heavy engineering and industrial fabrication, welding is not just a process — it’s the structural DNA that defines product integrity, operational safety, and regulatory compliance. Yet, many organizations still struggle with fragmented welding documentation, uncontrolled specification changes, and audit nightmares that escalate costs and compromise quality.

Our Welding Process Specification (WPS) Management Solution transforms welding administration into a fully digital, governed, and traceable system. It centralizes WPS creation, manages procedural qualifications (PQR), links welder certifications, and ensures absolute control over consumables — ensuring your welding operations meet the highest compliance standards with repeatable precision.

Key Use Cases & Capabilities

1. Standard and Custom WPS Templates

Easily create, standardize, and manage welding procedure specifications (WPS) for diverse project and code requirements.

Benefits:

-

-

Ensures template consistency across global teams

-

Simplifies setup for new welding jobs

-

Reduces non-conformance due to outdated procedures

2. Controlled Parameter Editing

Restrict who can edit welding parameters such as voltage, amperage, shielding gas, travel speed, and joint type.

Benefits:

-

-

Prevents unauthorized changes

-

Guarantees process consistency

-

Simplifies regulatory reviews

3. PQR Linking & Audit Trail

Seamlessly link WPS with Procedure Qualification Records (PQRs) and maintain complete traceability back to welder qualifications and tests.

Benefits:

-

-

Full audit trail for regulatory bodies

-

Eliminates data silos between qualification and production

-

Reduces certification renewal errors

4. Welding Consumables Tracking

Digitally track welding consumables and filler materials, fully aligned with active WPS parameters.

Benefits:

-

-

Minimizes material wastage

-

Improves forecasting for consumable procurement

-

Ensures consumables comply with specification limits

5. Multi-Code Compliance Management

Support compliance with multiple standards like ASME, ISO 9712, AWS, and internal company-specific codes.

Benefits:

6. Qualification Expiry & Renewal Alerts

Proactive notifications for upcoming qualification expirations for welders, WPS, and PQRs.

Benefits:

-

-

Prevents production halts due to expired certifications

-

Keeps personnel and procedures always certified

-

Ensures uninterrupted project execution

Role-Based Access & Interfaces

| Role |

Key Actions & Interface |

| Welding Engineer |

Create and maintain WPS/PQR, define parameters |

| Quality Inspector |

Review and approve specifications, validate compliance |

| Production Supervisor |

Assign qualified welders, allocate WPS to jobs |

| Compliance Officer |

Run audits, generate compliance reports |

| Admin |

Manage users, set access roles, configure standards |

Before vs After – Problem Solving Matrix

| Old Problem |

New Digital Solution |

| Paper-based WPS documents vulnerable to loss |

Centralized, version-controlled digital WPS library |

| Uncontrolled edits to critical welding parameters |

Role-based editing control and approval workflows |

| Manual tracking of qualification expiries |

Automated alerts for certifications and renewals |

| Disconnected PQR and WPS systems |

Fully linked WPS ↔ PQR ↔ Welder Qualification traceability |

| Consumable usage not aligned to WPS |

Digitally monitored consumable tracking tied to WPS |

Analytics & Dashboards

-

-

Real-time WPS usage status across projects

-

Qualification expiry timelines

-

Material consumption reports by project and welder

-

PQR compliance status dashboards

-

Non-conformance trends by welding parameter deviations

Use Case Impact – Real Industry Examples

Heavy Offshore Fabricator:

Reduced audit preparation time by 60% with fully linked digital WPS, PQR, and welder qualification modules.

Pressure Vessel Manufacturer:

Cut down non-conforming welds by 35% through controlled parameter editing and real-time WPS validations.

Pipeline Construction EPC:

Achieved 100% compliance readiness for ASME and ISO audits with automated documentation workflows.

Why Choose This Solution?

-

-

Purpose-built for industrial welding operations

-

Full WPS/PQR integration for seamless traceability

-

Reduces risk of compliance violations

-

Audit-ready documentation with minimal human intervention

-

Supports ASME, ISO 9712, AWS, and client-specific standards

-

Scalable for multi-site and multi-country deployments

-

Simplifies welder qualification management

Get Started

Looking to centralize your welding documentation, improve compliance readiness, and gain full control over your welding operations?

[Click here to schedule a demo]

by admin | Jun 6, 2025 | Engineering

In today’s complex manufacturing and heavy engineering environments, managing workforce productivity goes far beyond simply tracking attendance. With multiple work centers, variable shift patterns, overtime management, and non-productive hours, companies often struggle to capture a true picture of actual work performed versus allocated man-hours. Paper-based time sheets, disconnected systems, and subjective reporting add further layers of inefficiency and compliance risks.

Our Digital Job Time Card & Work Management Solution (DJTC) is purpose-built for this industrial reality. By offering real-time workforce analytics, digital time capture, and job costing at the work-center level, DJTC enables precise resource allocation, transparent reporting, and actionable productivity insights. It not only tracks active work but also captures idle and non-productive hours—providing a holistic view of labor utilization across shifts, departments, and projects.

Key Use Cases & Capabilities

1. Real-Time Digital Time Cards

Benefits:

2. User & Role-Based Workforce Management

-

-

Full user hierarchy setup: Manager → Shift Engineer → Supervisor → Worker → Shop In-Charge.

-

Dynamic mapping of teams, roles, and work centers.

Benefits:

3. Work Allocation & JTC Review Process

-

-

Allocate job time cards (JTC) to individuals or teams.

-

Review, approve, and track pending or completed JTCs.

Benefits:

-

-

Smooth approval workflows

-

Instant visibility into pending job completions

-

Improved supervisor oversight

4. OT (Overtime) Request & Approval Workflow

-

-

Systematic submission, review, and approval of overtime requests.

-

Historical OT data tracking.

Benefits:

5. K-JTC Self-Service Portal for Workers

Workers can:

-

-

View allocated jobs

-

Enter hours worked

-

View job history

-

Complete pending JTCs

Benefits:

6. Production Data Visibility Control

Benefits:

7. Multi-Dimensional Reporting Engine

Generate reports on:

-

-

General productivity

-

Worker efficiency

-

Job progress

-

Overtime analysis

Benefits:

8. Manual Attendance & Punching System

Benefits:

9. Workmen History Archive

Benefits:

-

-

Skills tracking

-

Performance audits

-

Compliance records

Role-Based Access & Interfaces

Role

|

Key Actions & Interface

|

| Production Manager |

Allocate jobs, monitor productivity, approve JTCs |

| Shift Engineer |

Assign JTCs, supervise work allocation, approve worker entries |

| Supervisor |

Validate worker time cards, track pending JTC completions |

| Worker |

Log hours, update job status, view personal work history |

| Admin |

Manage users, configure work centers, generate reports |

Before vs After – Problem Solving Matrix

Old Problem

|

New Digital Solution

|

| Paper-based job time tracking |

Digital JTC system with real-time logging |

| Inaccurate labor costing |

Shift-wise capture of productive vs idle hours |

| Unapproved or excess OT |

Role-based OT request & approval workflows |

| Manual work allocation confusion |

Centralized JTC work allocation & review process |

| Lack of historical worker data |

Complete workmen history with performance metrics |

Analytics & Dashboards

-

-

Workforce productivity dashboards

-

Job progress vs planned schedules

-

Idle and non-productive hour analysis

-

Shift-wise efficiency reporting

-

Overtime budget utilization

-

Historical performance trends by worker or team

Use Case Impact – Real Industry Examples

Fabrication Shopfloor:

Achieved 30% reduction in unproductive hours by accurately tracking non-productive time and aligning shifts accordingly.

Heavy Equipment Manufacturer:

Improved OT cost control by 25% with transparent overtime approval workflows.

Welding Operations:

Reduced shift overlap losses by 20% using JTC allocation visibility and real-time monitoring.

Why Choose This Solution?

-

-

Purpose-built for complex industrial shop floors

-

Accurate labor costing tied to real work progress

-

Full visibility into productive vs idle labor utilization

-

Built-in OT, attendance, and workforce history modules

-

Seamless integration with ERP, MES, and payroll systems

-

Scalable for small units to large multi-plant enterprises

-

Enables lean resource allocation and higher operational ROI

Get Started

Ready to digitize your workforce management and gain total visibility into job time, productivity, and cost?

Click here to schedule a demo for Digital Time Card

Click here to schedule a demo for Self Service Portals for workers